About Us

Guangdong Wealwell Technology Co., Ltd is specialized in smart toilet, smart toilet seat,concealed cistern and flushing fitting with 23 years’ experience.

Our factory locates in Guangdong Chaozhou and covers an area of 70,000 square meters. With R&D center is in Xiamen and Marketing center in Foshan.

Wealwell Technology has consistently adhered to its own R & D and design of products, and has obtained nearly 100 domestic and foreign patents and authoritative certifications.

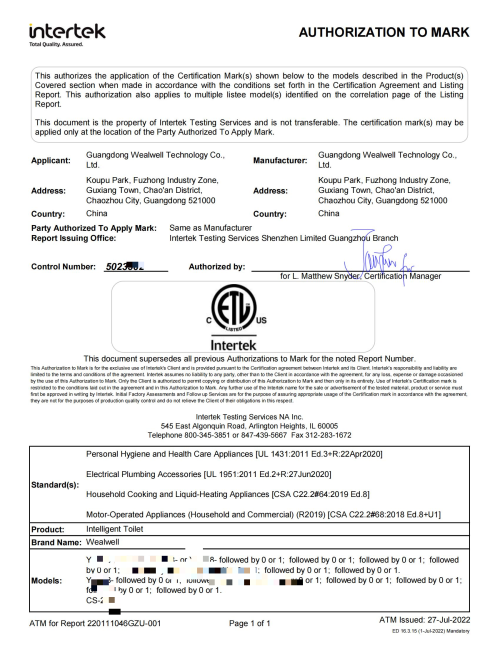

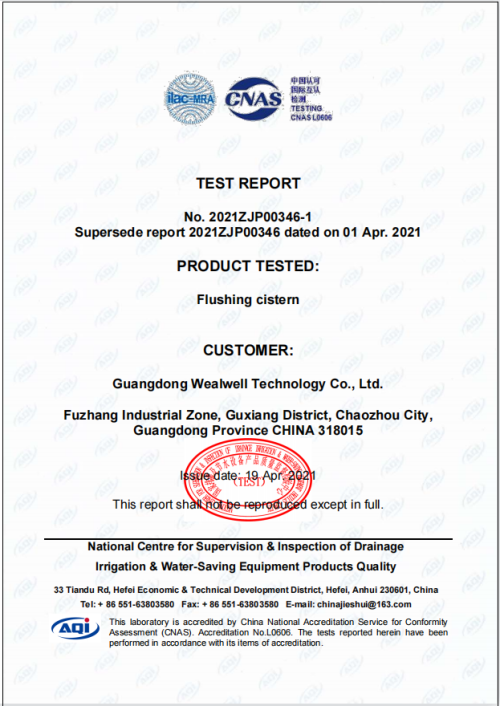

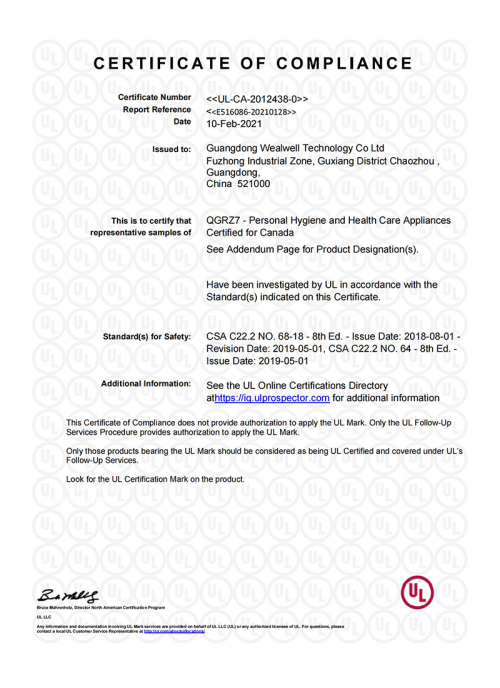

Wealwell products have passed ETL , CE, cUPC, UL,SAA, FCC, CQC, Watermark certification.

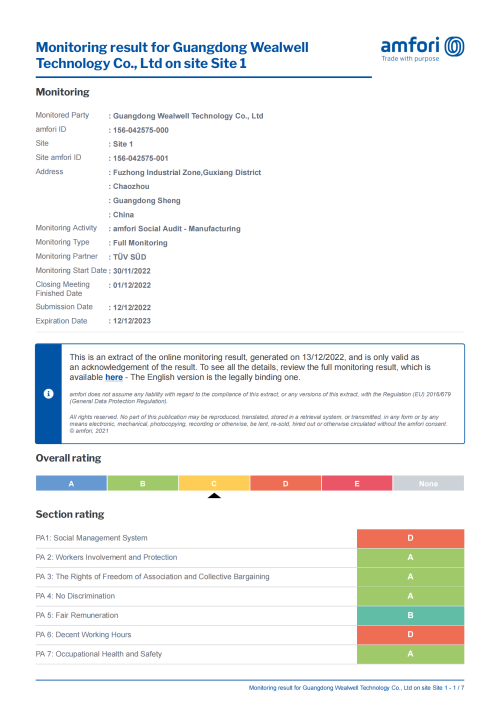

Our factory is in accordance with ISO9001, ISO14001 and BSCI International standardised management systems.

Our advantage:

One of the leading OEM and ODM supplier in the sanitary ware industry.

Innovative R & D capabilities: Wealwell product quality and innovative technology have reached the international leading level.

Core manufacturing capabilities : with 70000 square meters of large-scale production and manufacturing center .

Strict quality control system: Wealwell products are tested according to EU national standards.

Wealwell Technology is honor to be unit of drafting national standards for smart toilet, and China National Building Materials Smart Toilet R&D and test Base.

Innovative R&D capabilities

Professional R&D team develops and designs products with unique mold according to client’s requirement .

Wealwell technology currently has two R&D centers in Xiamen and Chaozhou, equipped with top-level intelligent R&D systems,

and has obtained nearly one hundred domestic and foreign patents and authoritative certifications,

We spend 20~30% of profit on product research and development every year,

and product quality and innovative technology have reached the international leading level.

Mold Center

Self-owned mold workshop is conducive to shortening the mold opening cycle, improving development efficiency, improving mold precision,

maintaining mold life, and escorting customers' new product launch cycle.

Central feeding system

The central automatic feeding is energy-saving and environmentally friendly, which is beneficial to reduce dust and blanking in the workshop,

ensure that raw materials are free from pollution, and improve product qualification rate and product quality.

Injection workshop

Take the lead in introducing international advanced automatic injection molding technology and equipment,

and continue to improve injection molding processing precision and production efficiency, making product quality more controllable and stable.

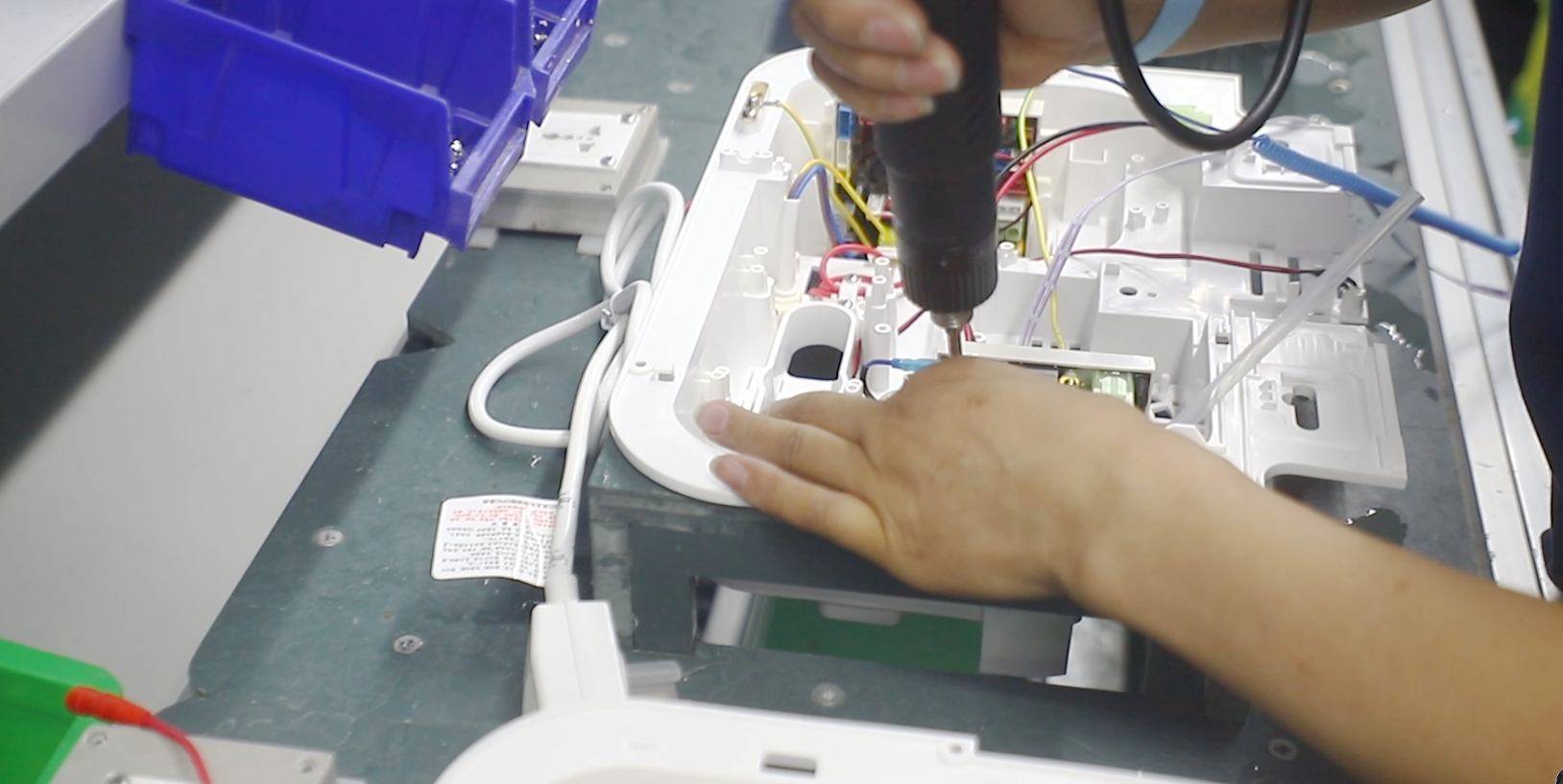

Smart toilet assembly workshop

Continuously upgrade the intelligent assembly workshop to improve production efficiency,

ensure product quality, and ensure stable delivery cycles for customers.

Smart toilet aging test line

The aging test assembly line has the advantages of convenient operation, friendly test environment, and high test efficiency.

It ensures the quality of the products and is responsible for each product.

Quality laboratory 110+ quality inspection

From the flow characteristics of raw materials to the performance test of new materials,

from the small batch trial production test of new products to the failure improvement countermeasures,

as well as the performance stability in harsh environments,

the reliability testing of machine functions and performance stability and functional components, etc., Achieve the perfection of every product.

IPX4 rain test

Normal temperature aging test

Programmable constant temperature and humidity detection

Type detection

Thermal shock test

Seat cover durability test

Constant pressure and constant flow valve detection

Fluid Heater test

Pulse solenoid valve detection

Cleaning component detection

Flow detection

Drop test

Simulated vehicle transportation vibration detection test

…………

ODM ability

As the leading OEM/ODM supplierin the sanitary ware industry, Wealwell has mastered the core independent molding technology,

and took the lead in introducing the industry's first constant temperature closed loop system

and precision CNC machining center and other large mold processing equipment.

We can understand your design concept and by presenting a perfect one-stop bathroom.

Our Certifications

Our Advantage

-

![R & D CAPABILITIES]()

R & D CAPABILITIES

Wealwell technology spends 20~30% of its profit on product research and development every year, and the product quality and innovative technology have reached the international leading level.

-

![OUR PRODUCTS]()

OUR PRODUCTS

The product quality and innovation ability have reached the international leading level, and customers are located in five continents and more than 60 countries.

-

![OUR CERTIFICATIONS]()

OUR CERTIFICATIONS

Wealwell products have passed E T L , C E, C U P C, U L,S A A, F C C, C Q C, Watermark certification .Our factory is in accordance with I S O 9 0 0 1 , I S O 1 4 0 0 1 and B S C I International standardised management systems.

-

![DELIVERY]()

DELIVERY

We pack each product carefully and deliver the goods to our customers on time.

-

![ODM CAPABILITY]()

ODM CAPABILITY

Wealwell technology has mastered the core independent molding technology, and has taken the lead in large-scale mold processing equipment such as constant temperature closed-loop system and precision CNC machining center.

-

![OUR SERVICE]()

OUR SERVICE

We will provide free product training, professional technical support and considerate product after-sales, and provide rich marketing materials for cooperative customers.

Brand Strength

-

![Strict quality control system]()

Strict quality control system

All our products are tested according to EU national standards, which are higher than the national standard. The mold materials are imported from Germany, and we insist on selecting high-quality raw materials.

-

![Core manufacturing capabilities]()

Core manufacturing capabilities

23 years of R&D and manufacturing experience, 70,000 square meters of mass production and manufacturing center, master the key links of core manufacturing.

-

![Mold development]()

Mold development

The professional R&D team develops and designs, and the products are independently moulded and customized on demand. Product quality and innovative technology have reached the international leading level.